2016 Gleason Bevel Gear Development Lab

Assets Purchased Outright from a Tier 1 Supplier Exiting the Business

Gleason Phoenix 280CX CNC Bevel Gear Cutter With AutoPath Chamfering

- Fanuc Control 30i Control

- Cutter Clamping

- Cutter Handling Bail For PENTAC

- Auxiliary Chamfering and Loader

- Part Probing - Electronic Contacting Gauge

- Chip Removal System For Dry Cutting

- Emergency Withdraw

- Electrics and Hydraulics to 480V/60Hz

- Foot Switch For Auxiliary Spindle

- Foot Switch For Workpiece

- Manual Pulse Generator

- USB Flash Drive W/SW Image

- Enhanced Fault Monitoring

- Diagnostics Via Ethernet

- Multi-Purpose Blowoff

SPECIFICATIONS:(Travel / Speed)

X-Horizontal, Work Slide: 25-334 mm / 13m/min

Y-Vertical Travel: +/-175mm / 13m/min

Z-Cutter Slide Travel: 125-600 mm / 13m/min

B-Root Angle: -5 Deg./+90 Deg. / 50 Deg/Sec

CAPACITY: (Face Milling / Face Hobbing)

Extreme Ratio: 200:1 / 200:1

Full Depth, Maximum: 20 mm / 20 mm

Face Width, Maximum: 58 mm / 58 mm

Range of Tooth Numbers: 1-200 Inclusive / 1-200 Inclusive

Maximum Gear Pitch Diameter: 280 mm / 280 mm

Maximum Cutter Size: 9" / 105 mm radius

Normal Module Range: 2-13 module / 2-13 module

Motor Drives: Speed / Continuous Torque Power

A-Work Spindle (Digital Direct Drive): 1200 rpm / 271 Nm

C-Cutter Spindle (Digital Direct Drive): 1200 rpm / 542 Nm

Electrical Equipment:

Coolant: AC Induction / 2.2kW

Hydraulic: AC Induction / 2.2kW

Chip Elevator: AC Induction / .4kW

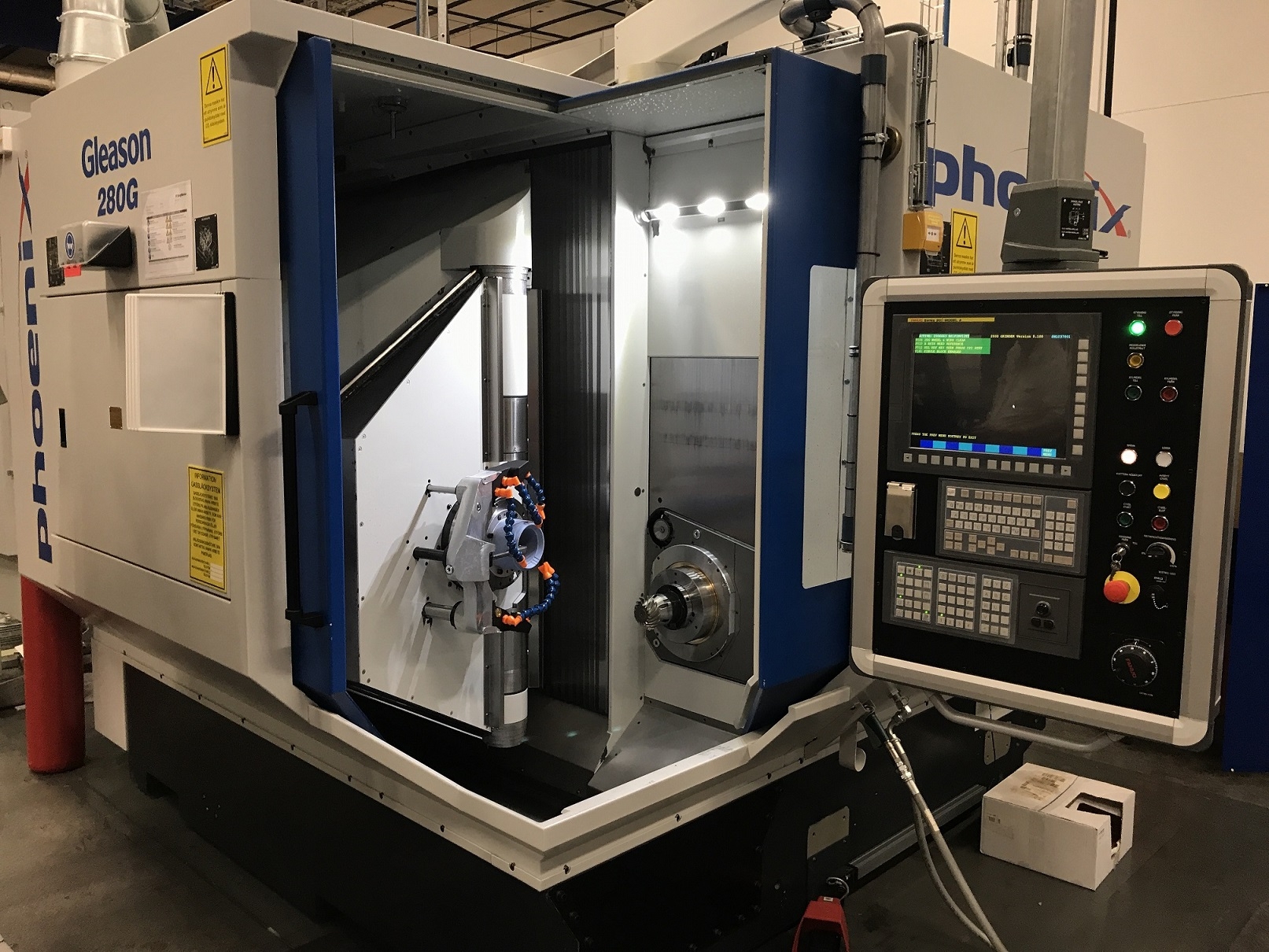

Gleason Phoenix 280G CNC Bevel Gear Grinder

- Fanuc 30i CNC Control

- Grinding Spindle W/Eccentric Motion

- Machine Arranged W/Grinding From Solid

- Machine Arranged W/Arbor Run-Out Compensation

- Wheel Mounting Equipment

- Emergency Withdraw

- Machine Axis Gauging

- Roughing Dresser Roller

- Finishing Dresser Roller

- Coolant Filter

- Cleanable Belt 480V/60Hz

- Electrics and Hydraulics to 480V/60Hz

SPECIFICATIONS:

X-Horizontal (work slide): 25-334mm, 1-13.1"

Y-Vertical Travel: -/+ 175mm, -/+ 7"

Z-Wheel Slide Travel: 125-600mm, 5-23"

B-Root Angle: -5 to +90deg

WORKPIECE CAPACITY:

Max. Full Depth: 20mm, .775"

Max. Face Width: 58mm, 2.3"

Max. Gear Pitch Diameter: 280mm, 11"

Min/Max. Wheel Size: 51/230mm, 2.0/9"

Max. Module: 10mm, 2.54 DP

Min. Number of Teeth: 1

ELECTRICAL EQUIPMENT:

X-Horizontal (work slide): 2,000 rpm

Y-Vertical Travel: 2,000 rpm

Z-Wheel Slide Travel: 2,000 rpm

B-Root Angle: 2,000 rpm

A-Work Spindle: 900 rpm

C-Wheel Spindle: 8,000 rpm

D-Dresser Spindle: 10,000 rpm

W-Eccentric Spindle: 2,800 rpm

Gleason 360T Universal Gear Tester

- Fanuc Control

- Machine Configured For Angular Bevel & Cylindrical

- Pivot Clamping For Swinging Gear Head Position

- Gear Spindle Motor Torque Extended Capacity

- Side Outboard Engagement By Tailstock Spindle

- Gear Spindle Drivetrain Configuration

- Nick & Burr Detection System - Enhanced Double Flank Method

- Workholding Quickchange Fixtures

- Networking Measurement Computer W/GEMS

- USB Flash Drive W/SW Image

- Foot Switch For Chucking

SPECIFICATIONS:

Maximum Gear Outside Diameter: 360 mm (14.2")

Maximum Pinion Outside Diameter: 340 mm (13.4")

Maximum Pinion Drive Speed: 3000 rpm

Maximum Gear Drive Speed: 1500 rpm

Offset Vertical 150 mm ( 5.9")

Pinion Cone Range:

(90) (135-350)

(70) (146-438)*

(110) (51-343)*

Gear Cone Range:

(90) (65-280)

(70) (78-306)*

(110) (56-284)*

Standard Testing Torque Load 2 to 90 Nm (1.5 to 66 ft-lb).

Parallel Axis - face-to-face 147 - 362

- Center Distance -7 - 250

Pinion Spindle Bore 39T

- Diameter 99.2 mm (3.9")

- Depth 419 mm (16.5")

Gear Spindle Bore 39T

- Diameter 99.2 mm (3.9")

- Depth 250 mm (9.8")

Gleason CB Cutter Build Stand

SPECIFICATIONS:

RSR Completing Extra Depth: 3.25" to 18"

RST Completing Standard Depth: 5" to 18"

RSR Alternate Standard Depth: 5" to 18"

RSR Alternate Extra Depth: 9"

Pentac and Tri-Ac Fine Pitch: 2.008" to 4.13"

Pentac and Tri-Ac Coarse Pitch: 2.95" to 6.89"

Cyclocut: 3.94" to 8.27"

Spindle Nose Taper: 2.29"