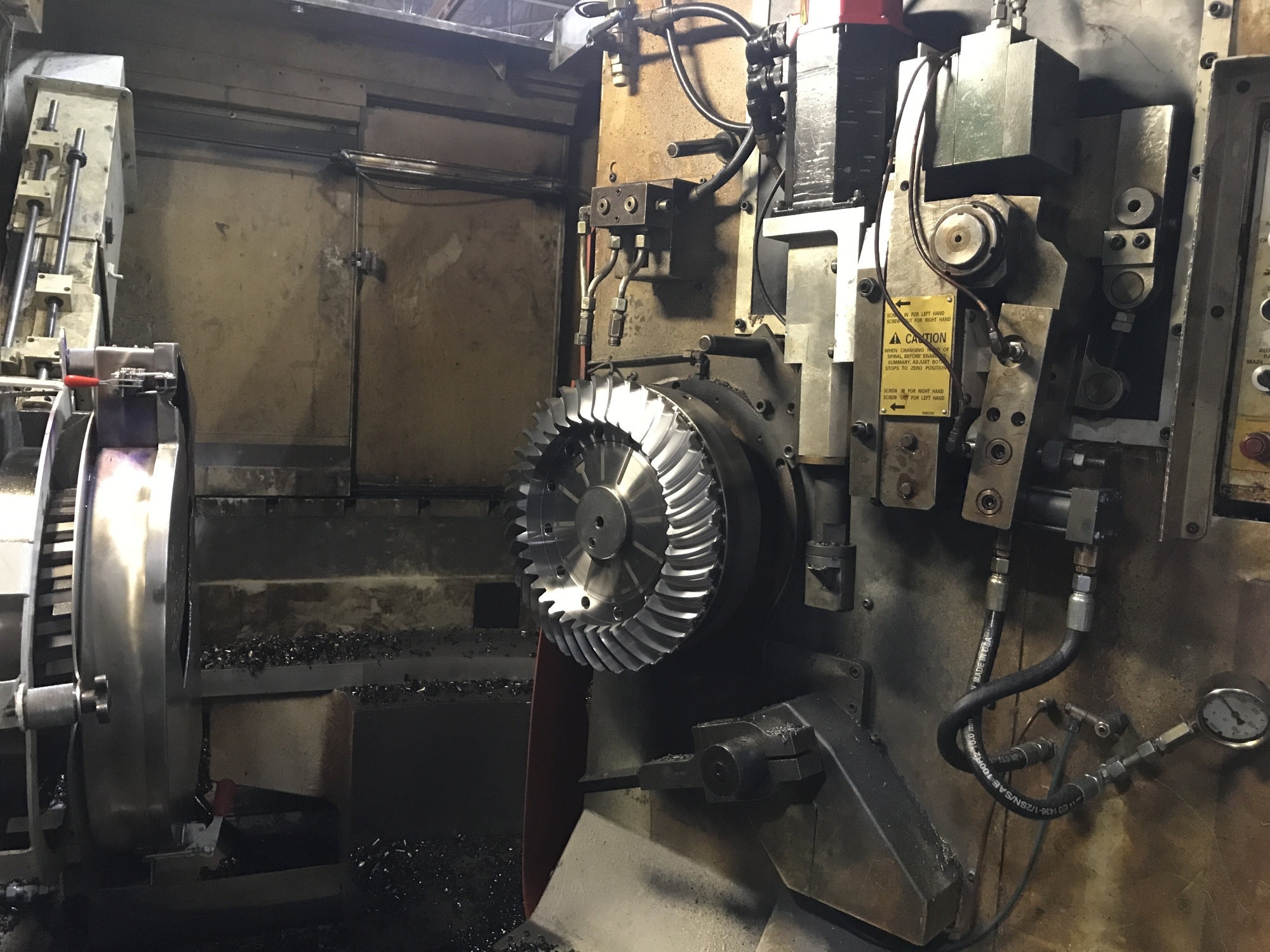

Automated Gleason Phoenix 1000HC CNC Flexible Large Bevel Gear Systems

Two Systems Currently in Operation

We are offering these two systems from the manufacturers floor.

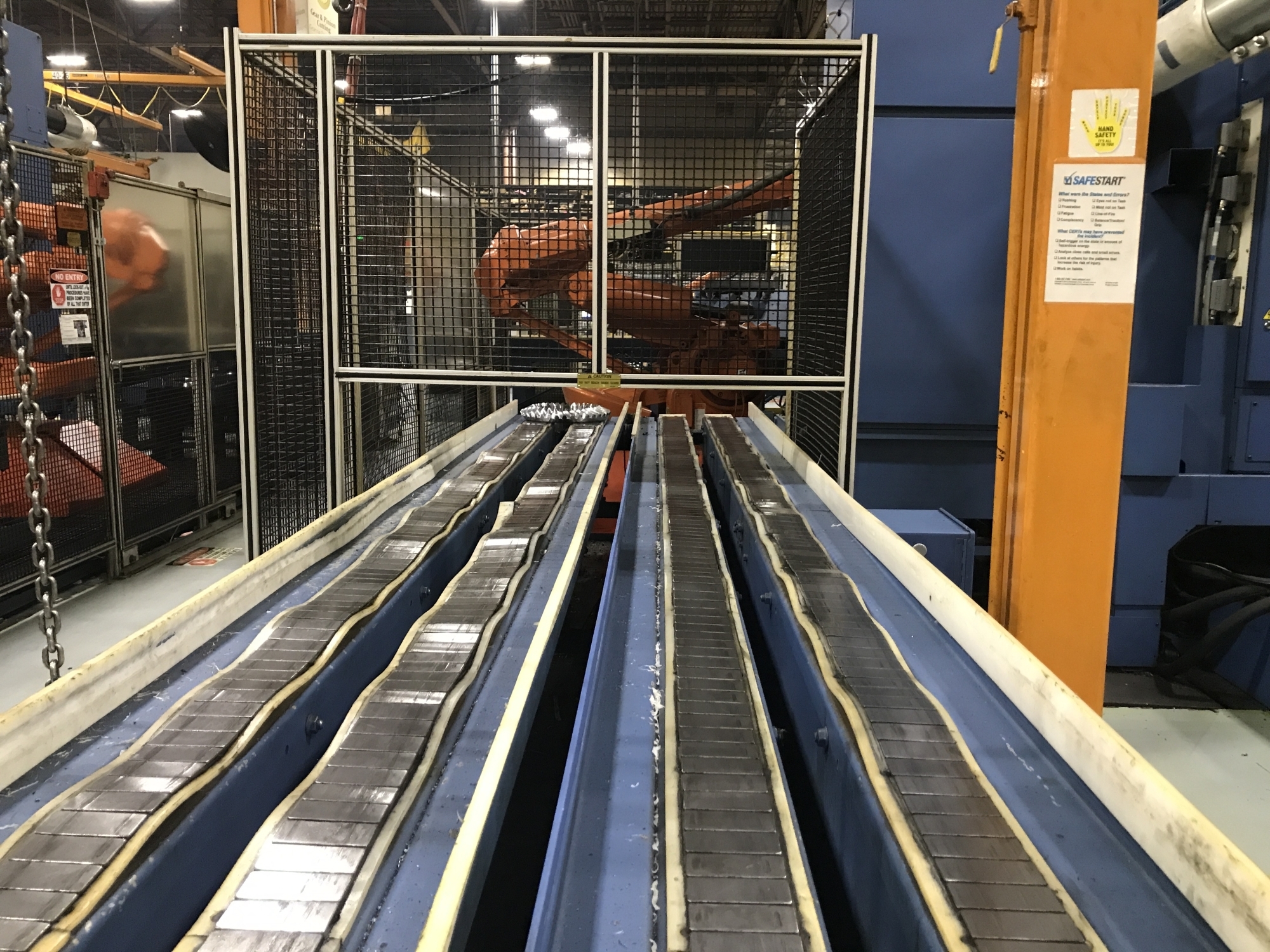

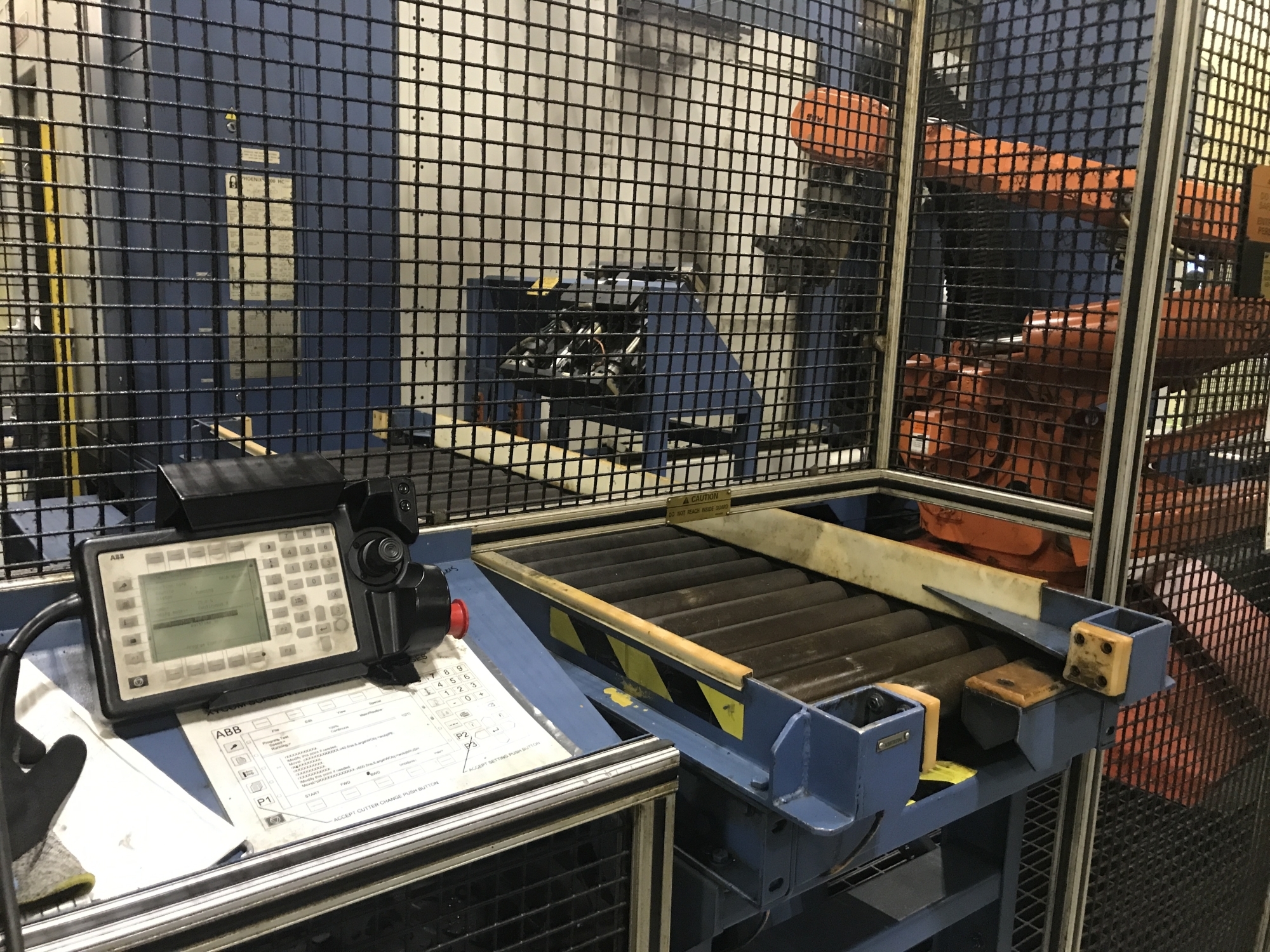

The gear blank is seated on the work spindle by an ABB Robot that receives the blank from a conveyor table at the rear of the machine. Once the robotic arm retreats, the machine runs its cycle. Upon cycle completion, the robot retrieves the completed bevel gear and places it on the finish side of the conveyor before loading the work spindle with a new gear blank. These machines are currently setup to run dry or wet cutting operations.

- Fanuc 150MB CNC Control

- UMC Software

- Dry Cutting

- Wet Cutting

- High Speed Spindle

- Chamfer Unit

- Coolant System

- Chip Conveyor

- Dry Shrouds

- Change Gears

- Robotic Loading System

- ABB Robot

- Gage Station

- Conveyor System

SYSTEM SPECIFICATIONS:

Extreme Ratio: Face Milling: 10:1, Face Hobbing: 10:1

Full Depth: Max: Face Milling:1.25" (31.75mm), Face Hobbing: 0.93" (23.50mm)

Face Width: Max: Face Milling:6.00" (152.00mm), Face Hobbing: 3.00" (76.20mm)

Range of Tooth Numbers: 1-300 Inclusive

Gear Pitch Diameter, Maximum: 1000 mm (39.37")

Cutter Size, Maximum: 18" (diameter) Face Milling

Cutter Size, Maximum: 350 mm (radis) Face Hobbing

Root Angle Range (B-Axis): 5 deg.to 90 deg.

Face Hobbing: 5 deg. to 90 deg. 9.00" Fixed, 229mm (Fixed)

A-Work Spindle: 0 to 67 RPM, 0 to 333 RPM

B-Swinging Base: 0 to 30 deg./sec, N/A

C-Cutter: 0 to 500 deg., Same

X-Horizontal: +/-305mm (+/-12")

Y-Vertical: +/-305 mm (+/-12")

Z-Sliding Base: -25/+700mm (-1/+28")

B-Root Angle: -5 Degree/+90 Degree

Diameter of Taper Hole at Large End: 8" (#80 Taper) to 6" (#60 Taper)

Taper Per Foot: 3/4", Same

Depth of Taper Front: 6", 152.40 mm

Depth of Bore: 678 mm (26.7")

Diameter of Taper Bore: 140 mm (5.5")

Diameter Through Spindle of Hole: 7.125", 180.98 mm

MACHINE DIMENSIONS:

Length x Width: 233"x 209", 5920 mm x 5310 mm

Height: 129", 3280 mm

Weight: 65,000 lbs., 29,484 kg